Toilet Paper Tissue Cutting Ma…

Automatic Facial Tissue Paper …

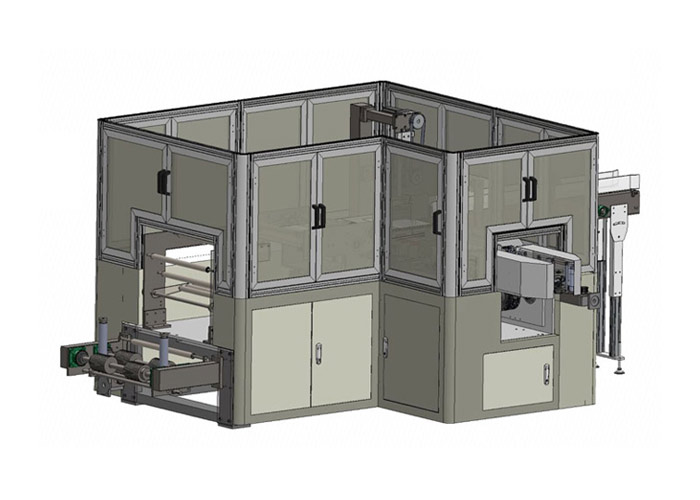

ST-100W Automatic Facial Tissu…

ST-100F Automatic Facial Tissu…

ST-100Y Cylinder Box Tissue Pa…

STR-150 Automatic Roll Tissue …

1. Seal moisture proof/dustproof effect is good.

2. Itis easy to open and unpack, as long as the opening and closing of the cable can beopenedin a week.

3. In the case of anti-counterfeiting, the logo can be printed on the easy line to identifythe authenticity.

Performance requirements:

1. The packaging machine can work continuously for 1 5 hours/day. .

2. Production capacity of the packaging machine, 10 30 bags/min.

Working principle and performance characteristics:

1. The machine adopts mechanical linkage as the main body, and adopts the principle of adhesive wrapping, and adopts multi-function digital display and frequency conversion stepless speedregulation; PLC programmable control design technology ,Automatic control, automatic feedingand automatic counting;

2. With the servo motor falling film, the stable air pump is equipped to assist the film to smooth the film and eliminate static interference.

3. The key electrical components adopt the Siemens brand to realize man-machine interface operation. Can complete programming, control operation, tracking display, card box overload.Dynamic protection, downtime;

4.The machine is equipped with the functions (commonly known as middle packing) of the whole process of assembling, palletizing, wrapping, sealing and fitting of single package.After the .packaging, the medicine is rich in aesthetics, intuitiveness and display, which greatly reducesthe packing cost and greatly replaces the heat shrink wrapping.

5. Enclosed full cover, chassis, platform and materials used in contact with the drug are made of high-quality health grade non-toxic 304 stainless steel. Fully comply with the GMP specificationrequirements of pharmaceutical production.

Performance technical parameters:

|

Packing Mat |

BOPP film,heat seal shrink film,PVC film |

|

Packing Speed |

10-30 bags/min |

|

Packing Size |

L:100-250mm,W:100-240mm,H:80-120mm |

|

Power Supply |

220V,50HZ |

|

Total Power |

6.5KW |

|

Work Pressure |

0.6MPa |

|

Machine Weight |

About 750KG |

|

Machine Size |

2270*810*2020mm |

Main Electrical List:

|

Item |

Name |

Brand |

Country |

|

1 |

Touch screen |

Weinview |

Taiwan |

|

2 |

Circuit breaker

|

TINCO |

China |

|

3 |

Programmable Controller |

MITSUBISHI |

Japan |

|

4 |

Small Relay |

CHNT |

China |

|

5 |

Solid State Relay |

Yangming |

Taiwan |

|

6 |

Travel switch |

Omron |

Japan |

|

7 |

Button switch |

Schneider |

French |